For any Florida fleet manager, few things are more stressful than a surprise roadside D.O.T. inspection. A failed inspection isn’t just a minor setback. It can mean costly fines, mandatory repairs, and—worst of all—an “Out-of-Service” (OOS) order that brings your operations to a grinding halt.

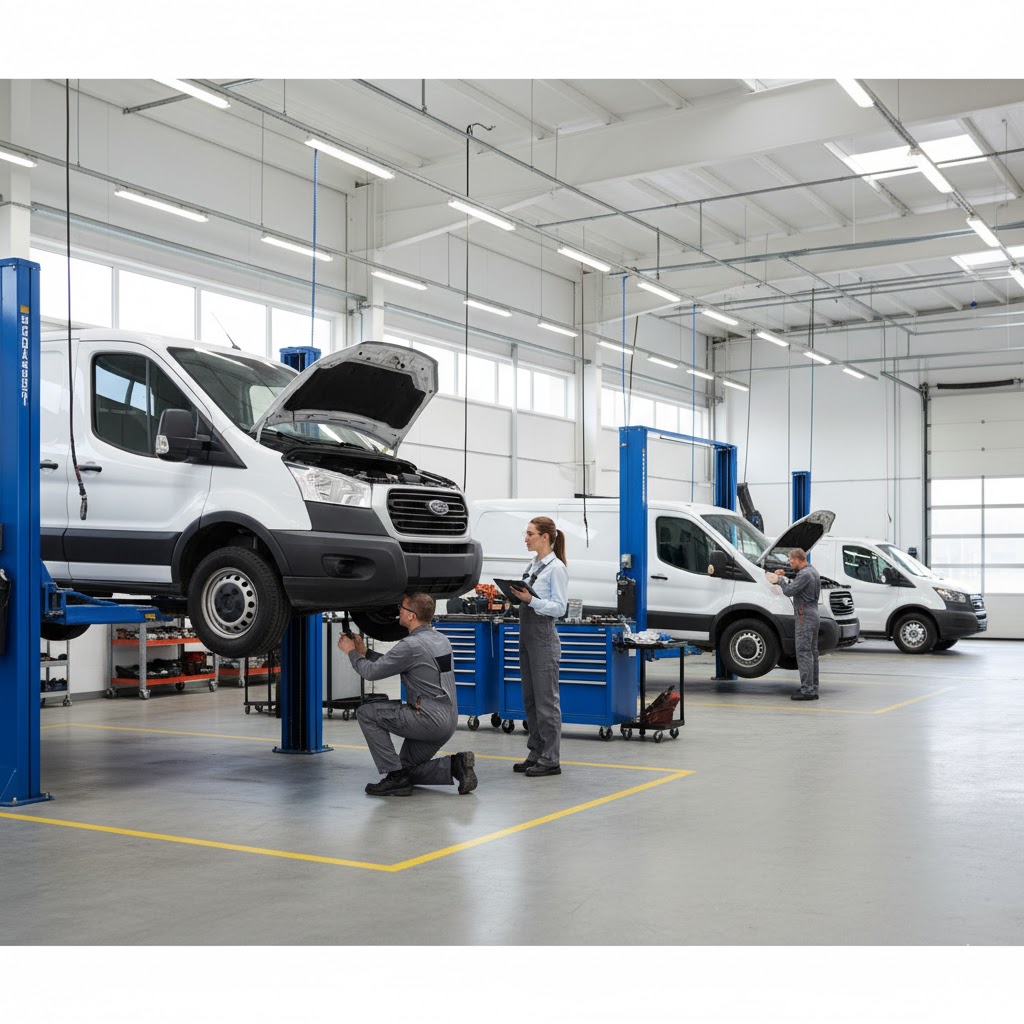

The Florida heat, constant humidity, and heavy stop-and-go traffic put unique stress on commercial vehicles. At Oil Can Man, we’ve serviced tens of thousands of fleet vehicles across South Florida since 1990. We know exactly what D.O.T. inspectors look for and why trucks fail.

Here are the 5 most common reasons we see for failed D.O.T. inspections, and how you can prevent them.

1. Brake System Failures

This is, without a doubt, the #1 reason trucks are placed out-of-service. Brake issues account for a massive percentage of all D.O.T. violations. Inspectors are trained to find them, and they look at everything:

- Worn Components: Brake pads, shoes, or drums worn past their limit.

- Air Leaks: Audible air leaks from lines, hoses, or chambers in the air brake system.

- Out-of-Adjustment Brakes: Slack adjusters that are not within the legal limits.

- Damaged Hoses: Chafed, cut, or cracked air hoses.

How to Prevent: Brakes must be a part of every single preventive maintenance check. Regular adjustments and inspections by a certified mechanic are non-negotiable.

2. Tire and Wheel Issues

Tires are one of the easiest things for an inspector to check, and they are a major safety focus. A-frame (steer) tires, in particular, are scrutinized.

Common failure points include:

- Tread Depth: Steer tires must have at least 4/32-inch tread, and all other tires at least 2/32-inch.

- Cuts and Damage: Any deep cuts, bulges, or signs of cord separation.

- Audible Air Leaks: Hissing sounds from the tire or valve stem.

- Mismatched Tires: Mixing radial and bias-ply tires on the same axle.

- Loose Hardware: Missing or loose lug nuts.

How to Prevent: Daily pre-trip inspections by the driver are key. Beyond that, your maintenance partner should be checking tire conditions and inflation during every service.

3. Inoperative Lights & Electrical

This one is frustrating because it’s often a simple fix, but it’s one of the most common violations. A D.O.T. inspector will walk around the vehicle and check every single light.

This includes:

- Headlights (high and low beams)

- Brake lights (including the center-mounted light)

- Turn signals (front, rear, and side)

- Clearance lights (on the truck and trailer)

- Reflective tape (if it’s missing, damaged, or obscured)

How to Prevent: Make a “light check” a mandatory part of your driver’s daily pre-trip. Keep spare bulbs and fuses on hand. During a PM service, your mechanic should check the wiring and connectors for corrosion, which is a major problem in Florida’s humid climate.

4. Fluid and Air Leaks

An inspector sees a puddle under your truck, and you’re already starting on the wrong foot. Active leaks are a clear sign of a mechanical issue.

Inspectors will look for:

- Oil Leaks: From the engine, transmission, or rear differential.

- Coolant Leaks: From the radiator, water pump, or hoses.

- Hydraulic Leaks: From power steering systems or liftgates.

- Air Leaks: (As mentioned in #1) Any audible leak from the brake system is a critical violation.

How to Prevent: A clean engine bay helps spot new leaks early. Our on-site technicians can identify the source of leaks during regular oil changes and address them before they become a D.O.T. violation.

5. Missing or Damaged Safety Equipment

This is the “low-hanging fruit” for inspectors. These violations are easy to spot and show a lack of attention to detail. Every commercial truck is required to carry specific safety items.

This includes:

- A properly charged and mounted fire extinguisher.

- A set of three reflective warning triangles.

- Spare fuses (if the vehicle uses them).

- Proper driver documentation (logbook or a functioning ELD, medical card, and driver’s license).

How to Prevent: Regularly audit your trucks to ensure all required safety equipment is present, mounted correctly, and in good working order.

How to Pass Every Time: The Proactive Solution

The secret to passing a D.O.T. inspection isn’t luck—it’s consistency.

Waiting until a problem occurs is too late. The only way to guarantee you pass is with a proactive, scheduled preventive maintenance program. This moves you from a reactive (fixing breakdowns) model to a preventive (avoiding breakdowns) model.

This is where Oil Can Man comes in. We don’t just perform the inspection; we build a maintenance plan to ensure you pass it.

Our mobile technicians come to your yard—on your schedule—and perform comprehensive checks. We find and fix the brake, tire, and lighting issues before they become a roadside violation.

Don’t Risk the Downtime. Get Inspection-Ready with Oil Can Man.

A failed D.O.T. inspection can cost you thousands in fines and lost revenue. Don’t leave it to chance.

Oil Can Man provides complete, certified D.O.T. inspection services for your entire fleet. Our certified technicians will come to your location, perform a thorough inspection, and provide a detailed report on any issues that need to be addressed.

Keep your fleet compliant, safe, and on the road.

Contact Oil Can Man today to schedule your fleet’s D.O.T. inspections and build a preventive maintenance plan that saves you time and money